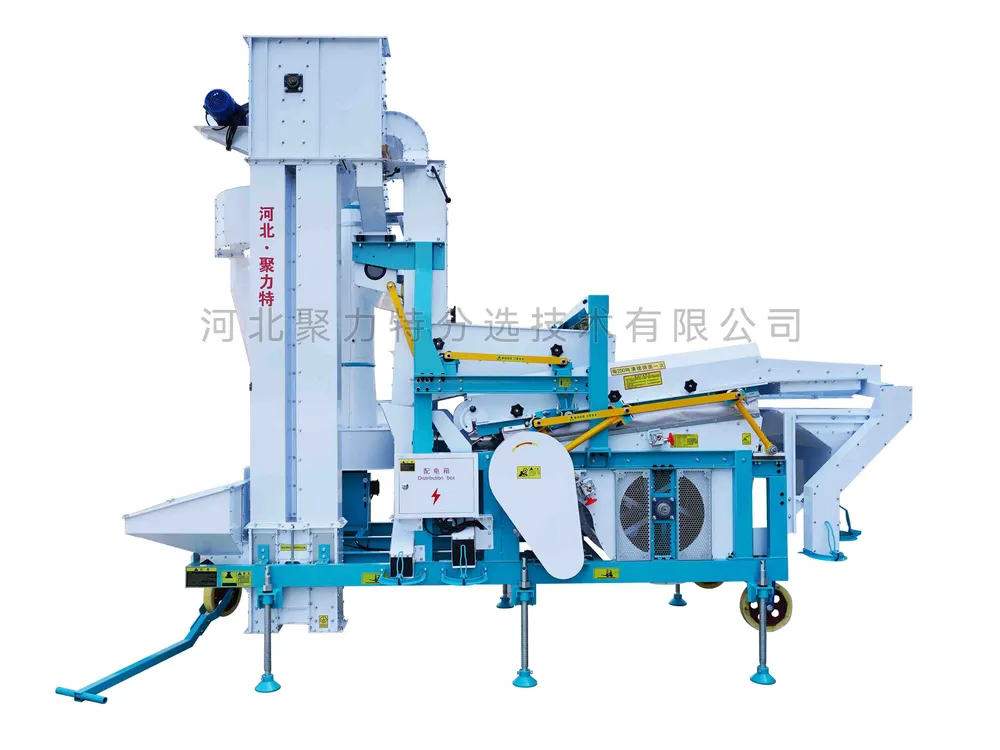

5XFZ-25SC Air-screen Cleaner with Gravity Table

- Model : 5XFZ-25SC

- Purity: 99%

- Sieve Size(mm) : Gravity sieve1700 x 1600 \ Front sieve1250 x 1200

- Power(kw) : 12.1

Доставка

Срокът на доставка обикновено варира от 15 до 30 работни дни след потвърждаване на поръчката, в зависимост от конфигурацията на продукта, производствения график и местоназначението. Всички машини са надеждно опаковани за безопасно транспортиране. Точните срокове за доставка, начинът на доставка и подробностите за проследяване ще бъдат потвърдени преди изпращането.

Описание

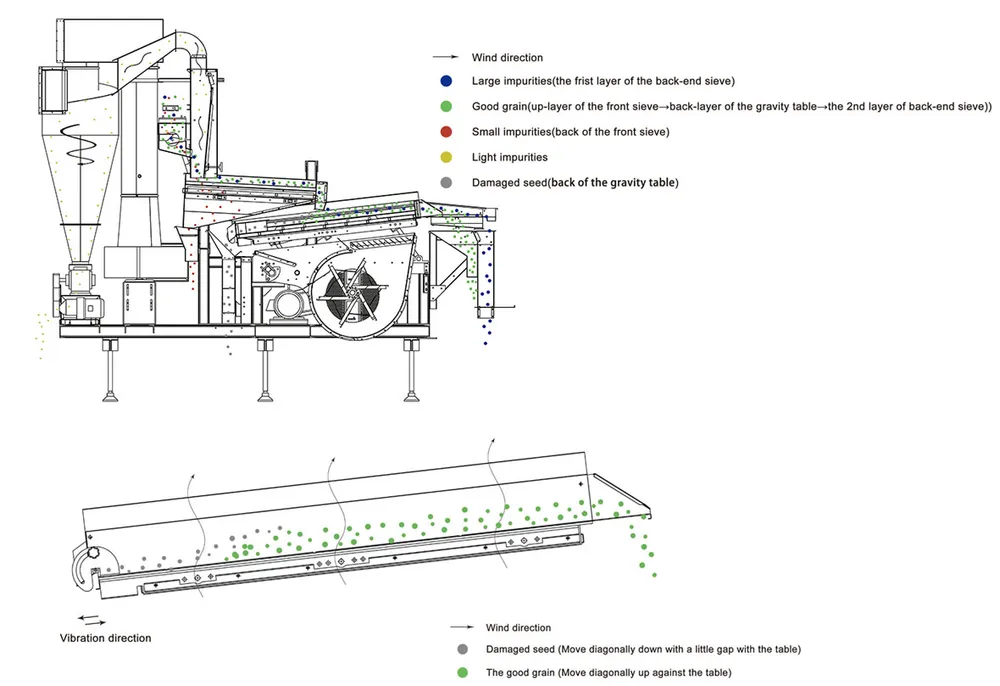

This machine consists of ultra low speed, no broken elevator, vertical air screen, cyclone dedusting system, large proportion platform, vibrating and grading screen. It can remove dust, chaff, shell and other light impurities. It can also remove the blighted seed, budding seed, damaged seed (by insect), rotten seed, deteriorated seed, moldy seed, non-viable seed, seed with black powder sick. After the large and small impurities have removed, the finished product can be divided into best, medium and small particles.

Features

- This machine can replace gravity separator, reduce the load of gravity table and increase production further.

- For the processing of wheat, rice, corn, soybean, sorghum and other commodity grains, productivity can reach 20t/h, and can remove more than 90% kinds of light impurities from grain.

- Complete wind selection, gravity selection, screening and grading, which can save energy and reduce consumption and labor.

- Environmental cyclone duster system and without a lot of dust leakage.

- It can be equipped with elevator, screw conveyor and belt conveyor.

Advantages

The front sieve can remove small impurities, which can reduce the load of gravity table and blockage of small particles. The machine can also remove kinds of light and small impurities, which improves the selection of proportion greatly.

| Model | 5XFZ-25SC |

|---|---|

| Purity | 99% |

| Sieve Size(mm) | Gravity sieve1700 x 1600 \ Front sieve1250 x 1200 |

| Power(kw) | 12.1 |

| Capacity(t/h) | 10-15 |

| Weight(T) | 2.20 |

| Overall size L x W x H(mm) | 4411x2786x3735 |