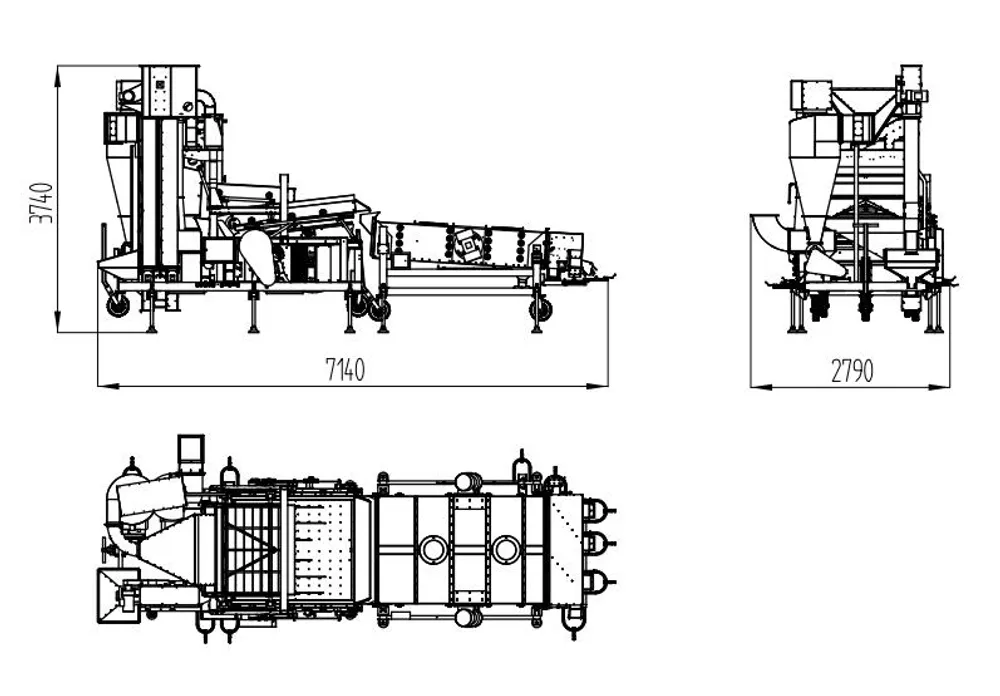

5XFZ-25S Air Screen Cleaner With Gravity Table & 5XFJ-10C Vibration Grader

- Model:: 5XFZ-25S Air Screen Cleaner With Gravity Table & 5XFJ-10C Vibration Grader

- Power(kw):: 13.6

- Weight(kg):: 3400

- Voltage:: 380V, 50HZ, Three Phases

Delivery

Delivery duration typically ranges from 15 to 30 working days after order confirmation, depending on product configuration, production schedule, and destination. All machines are securely packed for safe transportation. Exact delivery timelines, shipping method, and tracking details will be confirmed prior to dispatch.

Description

It always used for the soybean, peanut, sesame cleaning, and capacity can reach to 10-15t/h. Purity can be more than 99%.

Function

It is to remove dust, leaf, light impurity by the air screen. And remove above 90% bad seed, like blighted seed, budding seed, damaged seed (by insect), rotten seed, deteriorated seed, moldy seed, non-viable seed, seed with black powder sick by the gravity table. Remove the big impurity from the back half screen.

Selling Point

It always used for the soybean, peanut, sesame cleaning, and capacity can reach to 10-15t/h. Purity can be more than 99%

| Model: | 5XFZ-25S Air Screen Cleaner With Gravity Table & 5XFJ-10C Vibration Grader |

|---|---|

| Power(kw): | 13.6 |

| Weight(kg): | 3400 |

| Voltage: | 380V, 50HZ, Three Phases |

| Sieve Size: | Gravity Table:1700mmx1600mm |

| Capacity(t/h): | 10t/h for seeds, 15t/h for commdity grains |

| Overall Size L×W×H(mm): | 7140x2790x3740 |