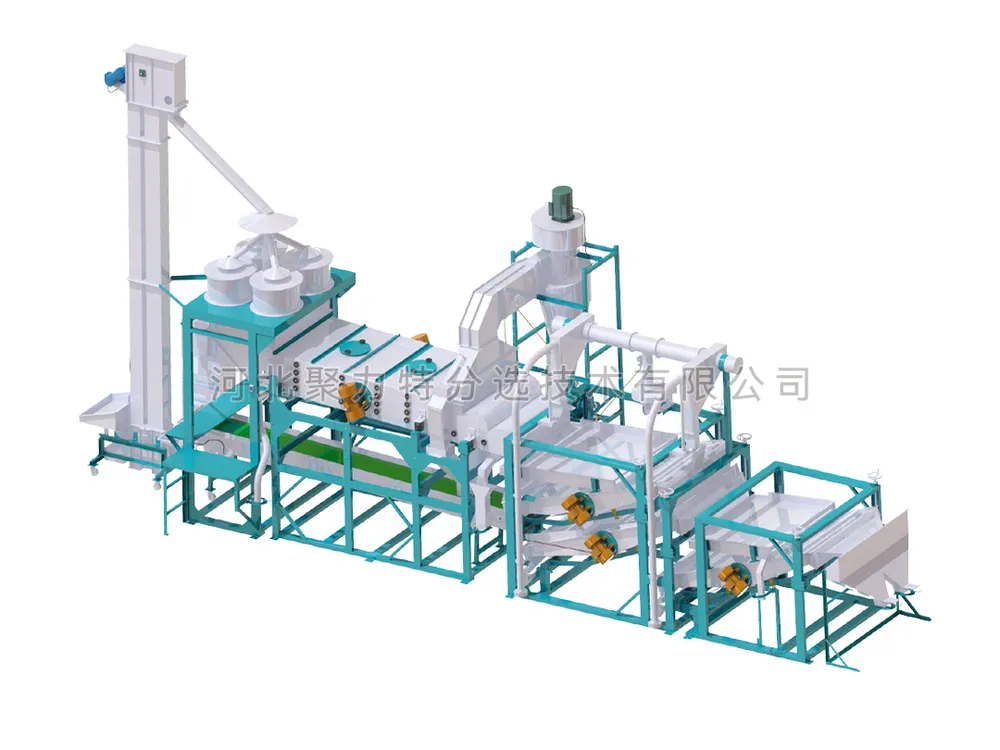

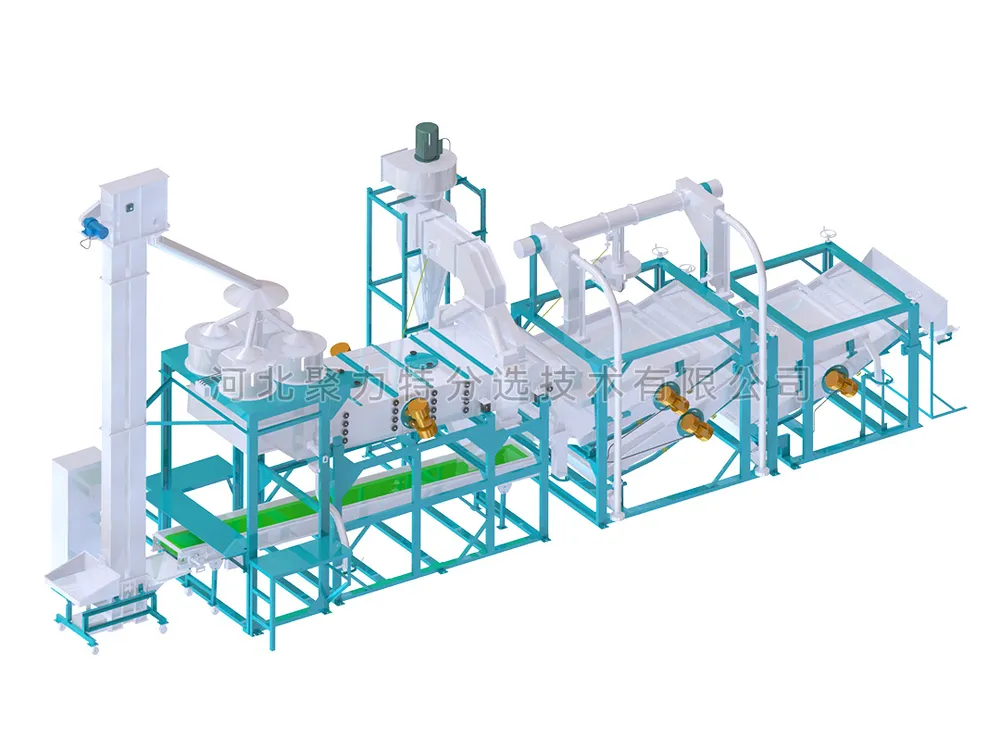

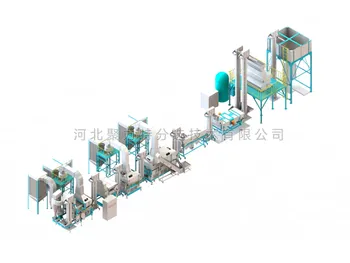

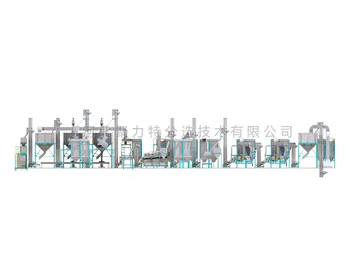

Sunflower Seed Shelling Processing Line

Delivery

Delivery duration typically ranges from 15 to 30 working days after order confirmation, depending on product configuration, production schedule, and destination. All machines are securely packed for safe transportation. Exact delivery timelines, shipping method, and tracking details will be confirmed prior to dispatch.

Description

The sunflower seed shelling and dehulling processing line is designed to efficiently remove the outer shell from sunflower seeds while maintaining a high kernel integrity rate. Through precise mechanical impact, airflow separation, and screening processes, the system separates shells from kernels with minimal breakage.

Functions

This sunflower seed shelling line is designed to efficiently remove the outer shell from sunflower seeds with a stable processing capacity of 0.8–1.2 tons per hour. The process starts with an elevator that feeds sunflower seeds evenly into the shelling machine, where the shells are cracked and separated from the kernels. A vibration grader then separates shells from kernels based on size and shape, followed by a gravity table that further separates kernels from residual shells and light impurities by specific gravity. The result is clean, high-quality sunflower seed kernels suitable for further processing or packaging.